Enhancing Efficiency & Accuracy in Material Handling: The Purpose & Benefits of Belt Weighers

In the Australian bulk materials handling sector, accuracy and efficiency are paramount. Explore the purpose & benefits of Belt Weighers.

In the Australian bulk materials handling sector, accuracy and efficiency are paramount. Whether it’s in industries like mining, agriculture, or manufacturing, the precise measurement and management of materials can significantly impact operations and bottom lines. One technology that has emerged as an important player in this regard is the belt weigher, a sophisticated instrument designed to precisely measure the flow rate and totalised weight of materials transported on conveyor belts. Let’s delve into the purpose and benefits of belt weighers, exploring how they enhance efficiency and accuracy in material handling processes.

The Purpose of Belt Weighers

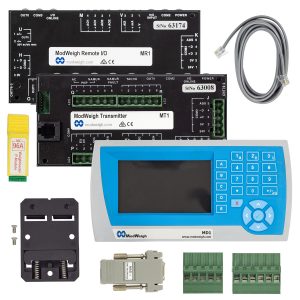

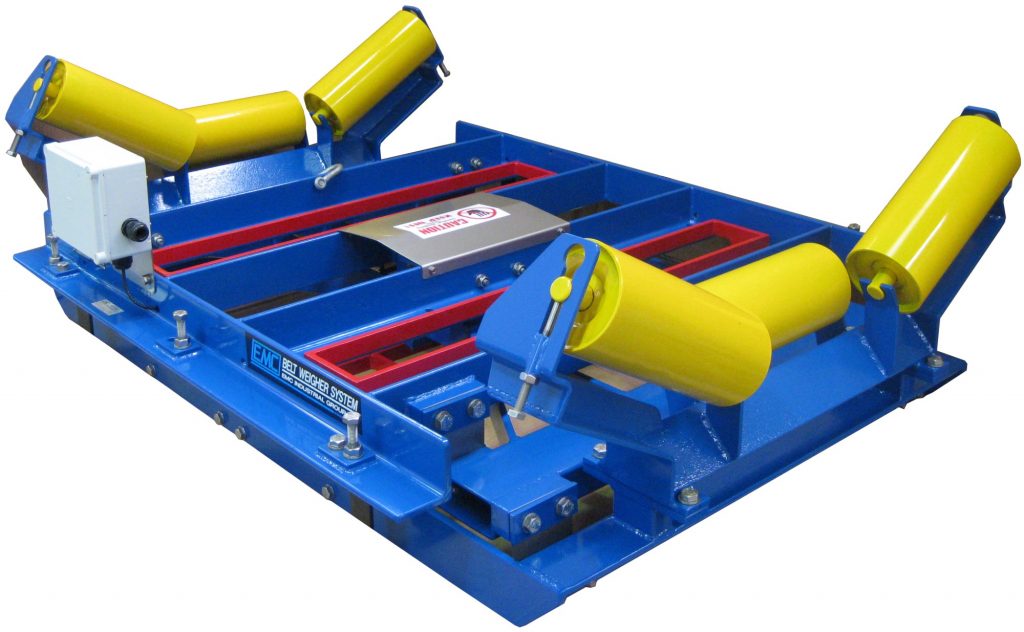

Belt weighers, also known as conveyor belt scales or weigh belt feeders, are specialised instruments utilised to measure the flow rate and totalised weight of bulk materials as they move along conveyor belts. They consist of load cells integrated into the conveyor system, electronic integrators, and software that interprets the data. The primary purpose of belt weighers is to provide accurate, real-time information on the amount of material being transported, allowing operators to monitor & control the flow with precision.

These systems are employed in a wide range of industries & applications, including:

Mining & Quarrying

Belt weighers are crucial in mining operations for monitoring the flow of ore, coal, and other extracted materials. They ensure accurate inventory management and optimise the efficiency of material transport from extraction sites to processing facilities.

Agriculture

In agriculture, belt weighers are used in grain handling facilities, feed mills, and fertiliser plants to precisely measure the quantity of crops, grains, and other agricultural products being transported on conveyor belts. This data enables farmers and agribusinesses to manage inventory, monitor yield, and streamline production processes.

Manufacturing

In manufacturing facilities, belt weighers play a vital role in material handling processes, ensuring accurate dosing and batching of raw materials in various production stages. They help maintain consistency in product quality & minimise waste by precisely controlling material flow.

Ports & Terminals

Belt weighers are utilised in ports and terminals for loading and unloading bulk cargo such as coal, grain, and aggregates. They facilitate efficient logistics management by accurately measuring the quantity of materials being transferred between ships, trucks, and storage facilities.

Benefits of Belt Weighers

The integration of belt weighers into material handling systems offers several key benefits:

Accuracy

Belt weighers provide highly accurate measurements of material flow, minimising discrepancies and errors in inventory management. This precision ensures that businesses have reliable data for decision-making, such as inventory control, process optimisation, and billing accuracy.

Efficiency

By accurately measuring material flow rates, belt weighers enable operators to optimise conveyor speeds and feeding rates, maximising throughput while minimising downtime and energy consumption. This increased efficiency translates to higher productivity and reduced operational costs over time.

Inventory Management

Belt weighers facilitate real-time monitoring of material inventories, allowing businesses to maintain optimal stock levels and prevent stockouts or overages. This proactive approach to inventory management helps streamline supply chain operations and improve overall logistics efficiency.

Quality Control

In manufacturing processes, belt weighers contribute to quality control by ensuring precise dosing and blending of raw materials. This helps maintain consistency in product quality and minimises variations that could lead to defects or rework.

Compliance & Reporting

Belt weighers can generate comprehensive reports and data logs documenting material flow rates, totalised weights, and other relevant metrics. These reports are invaluable for regulatory compliance, performance analysis, and auditing purposes.

Cost Savings

By optimising material handling processes and minimising waste, belt weighers contribute to significant cost savings over the long term. Whether through reduced energy consumption, improved inventory management, or enhanced productivity, the return on investment for implementing belt weighers can be substantial.

Belt weighers are indispensable tools for enhancing efficiency and accuracy in material handling operations across various Australian industries. By providing precise measurements of material flow rates and totalised weights, these sophisticated instruments empower businesses to optimise processes, improve inventory management, and control costs effectively. As industries continue to prioritise operational excellence & sustainability, the adoption of belt weighers is likely to become increasingly widespread, driving greater efficiency and profitability in material handling practices and creating a higher demand of products like EMC’s & ModWeigh’s Belt Weigher’s range.

Product Range