World-Class Corrosion Resource Facility Complete

Together with a Chevron and Curtin University, Automation & Control has helped build a new facility that simulates offshore conditions to tackle corrosion.

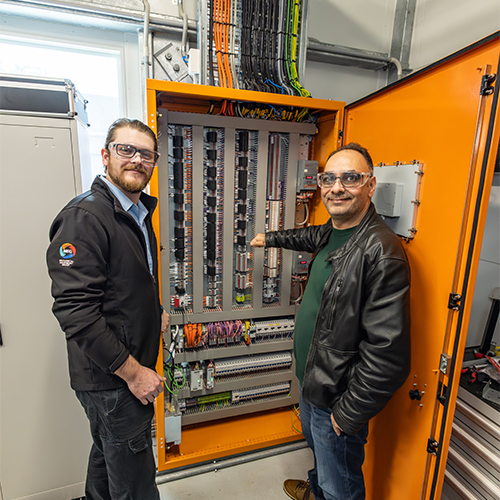

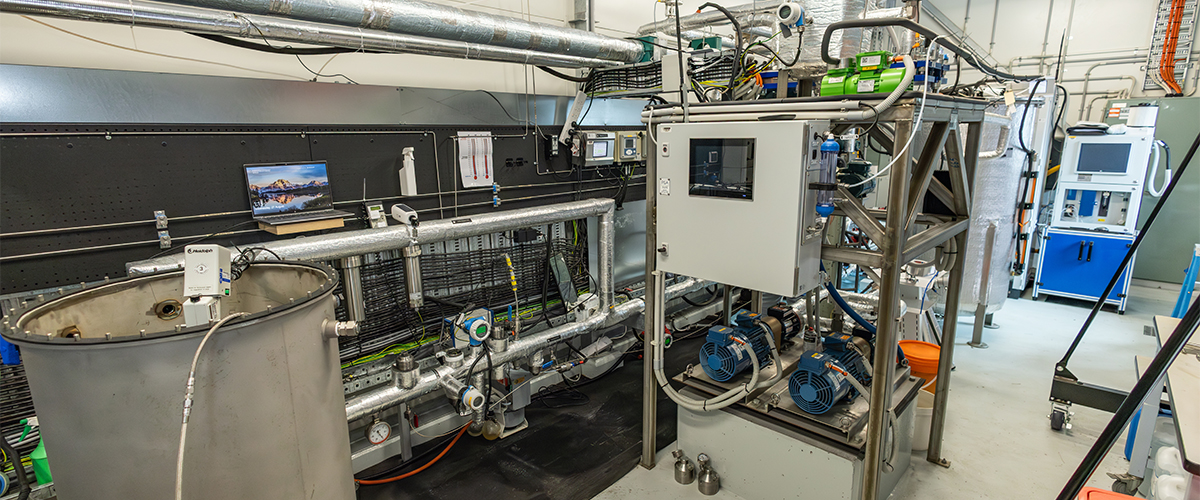

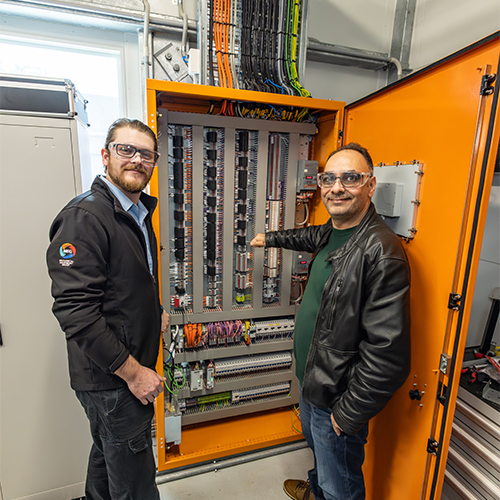

Curtin University, in partnership with Chevron, has launched a $4 million Extreme Service Flow Loop facility that replicates harsh offshore pipeline conditions to investigate corrosion risks. A key element of the project is the custom control board and integrated control system designed, built, installed and tested by our team, enabling precise operation, monitoring and data capture within the complex testing environment. This instrumentation supports advanced research into pipeline integrity, safety and long-term performance.

Problem

The project required control equipment for a cutting-edge facility designed to replicate extreme offshore environments to test and predict corrosion impacts on pipeline materials and instrumentation. The work demanded strict attention to safety, environmental protection, and operational efficiency.

The testing process also relied on complex automation and control requirements that continued to evolve, with frequent specification changes and updated functional needs that had to be incorporated without disrupting project momentum.

Project Solution

We provided a custom automation system control board, flow management hardware, sensors and control software. We seamlessly integrated these components to manage the testing environment efficiently.

Our solution allowed precise operational control and real-time parameter adjustments based on data, ensuring accurate simulation of corrosive conditions. We also implemented reliable data monitoring to support safe and effective experimental outcomes. Our expertise in design, installation and commissioning was key to the project’s success.

Impact

Our automation framework was central to enabling state-of-the-art research into offshore pipeline corrosion within the facility. By delivering a robust, reliable control infrastructure, we have enhanced the ability to monitor and understand gas behaviour and corrosion mechanisms under realistic conditions.

This supports safer, more efficient and cost-effective resource development while ensuring environmental protection, workforce safety and infrastructure resilience. Our automation solution contributes to advancing industry practices and delivering significant societal benefits in the energy sector.

Videos

Equipment Used

- Sensors and instruments for real-time monitoring

- Selection of durable materials suited to harsh environmental testing

- Experienced engineers specialising in automation and control system integration