WEG CFW11 Frequency Inverter

High-performance, simplicity of installation and energy-efficient solutions. WEG frequency inverters use cutting-edge technology for the speed variation of three-phase induction motors.

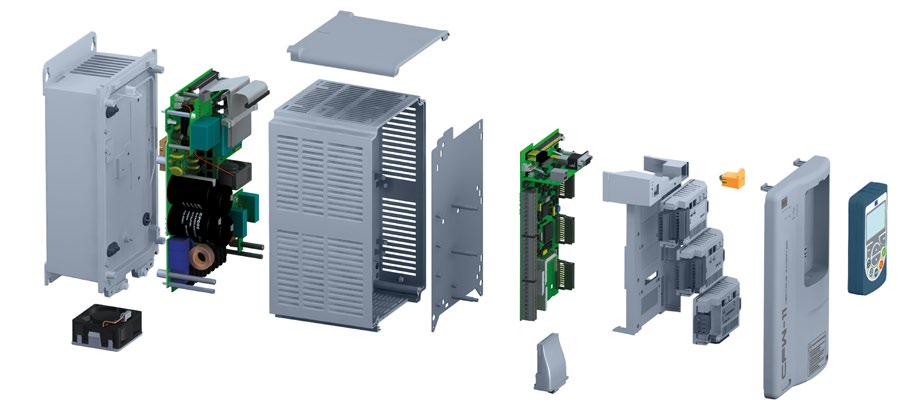

With high technology for control of three-phase induction motors and permanent magnets synchronous motors – Magnet, the CFW11 Series achieves the performance increase for the most complex drive systems. Design exclusive for industrial or professional use, the CFW11 presents many innovations adding significant benefits to customers, a lot for its simplicity of installation and operation, based in the Plug-and-Play philosophy also allowing simple and quick installation of its accessories.

Main characteristics

- Power supply

- Built-in inductors on the DC Link

- Space saving in the panel

- Built-in USB port

- Inverter smart cooling system

- Several communication protocols available (Modbus-RTU, Modbus-TCP, Profibus-DP-V1, DeviceNet, CANopen, EtherNet/IP, EtherCAT, PROFINET-IO and BACnet)

- Version with cabinet with degree of protection IP55 (versions with built-in switch-disconnector)

- High precision and reliability in speed and torque control

- Robust hardware

Easy to Use

The CFW11 has many useful and convenient functions for the customers, especially because of its simple installation and operation. The CFW11 has been designed based on the plug-and-play technology, which allows a simple and quick installation of the inverter and its accessories. The HMI has a navigation and programming system with soft keys. You can access the parameters sequentially or through parameter groups.

The HMI also offers the oriented start-up function that guides the user along the programming.

Flexibility

The CFW11 is adaptable to the customer’s needs through a wide range of easy-to-install accessories. In addition, the standard version comes with SoftPLC, allowing the customers to create their own applications using the WLP (Ladder Programming) software application.

Connectivity

Communication protocols: Modbus-RTU, Modbus-TCP, Profibus-DP-V1, DeviceNet, CANopen, EtherNet/IP, EtherCAT, PROFINET-IO and BACnet.

Vectrue Technology®

- Linear and adjustable V/F, VVW (Voltage Vector WEG) and vector control are available on CFW11

- Two types of vector control: sensorless and closed loop vector control (encoder Interface required)

- Sensorless vector control permits high torque and quick response in open loop, even at low speeds

- The self-tuning function sets the vector control or VVW with the motor and to application load used

- By the adjustable V/F control, it is possible, for example, to adjust a quadratic V/F curve, providing energy savings for quadratic torque loads (e.g.: centrifugal pumps and fans)

Optimal Braking®

Applications involving high inertia loads, when applied short time deceleration, a large amount of energy returns from the motor to the VSD. To handle this energy, regular VSDs have to dissipate it as heat in power resistors. Such resistors are usually large and some installation criteria must be considered due to their heat dissipation. As an alternative to the use of braking resistors, CFW11 features a special braking method in vector control mode known as Optimal Braking®. This innovation delivers a high-performance braking torque without requiring a braking resistor. The following graph shows the advantages of using Optimal Braking® compared to other braking methods, thus ensuring an optimized and low-cost solution for braking applications.

SoftPLC Function

It is a resource that provides PLC features to the CFW11 without the addition of any accessories. It provides flexibility to the product, allowing the user to create his/her own applicative software (user’s program).

Features

- Ladder language programming using WLP Software

- Access to all VSD parameters and I/Os

- Configurable PLC, mathematical & control blocks

- Applicative software download, upload & online monitoring via USB connection

- Storage of user application in the CFW11 flash memory module (see below)

- Memory capacity of 15 kB for user application storage

Remote Keypad

The keypad can be installed on panel doors or machine consoles with an IP56 protection degree.

Applications

- Pumps & Fans

- Compressors

- Multipump Control

- Load Lifting

- Machine Manufacturers & Processes in General

- Paper & Cellulose

- Wood

- Cement

- Mining

- Petrochemical or Chemical

- Steel Plant

- Metallurgy

- Refrigeration

- Sugar & Alcohol

Resources

With decades of experience in developing electronic products, WEG offers high-performance and efficiency solutions in drives for industrial electric motors. Developed in compliance with international standards, WEG drives offer flexibility and innovation to increase the productivity and reliability of your processes.

We offer site consultation, installation & maintenance for all your requirements.